The new generation of Goldhofer semi lowloaders combines Goldhofer’s proven high standard of engineering with attractive pricing plus practical details such as an intelligent load securing system.

With the user-friendly self-tracking semi lowloaders in the »STEPSTAR« series, you are ideally equipped for everyday haulage operations with payloads of up to 70 t.

EFFICIENTLY WITH 26.3 t PAYLOAD

The self-tracking »STEPSTAR« semi lowloaders come with an outstanding payload-to-weight ratio. The advanced design of the »STEPSTAR« results in significant weight savings over comparable vehicles and thus an increased payload of 1 t or more. That is the key to efficient and economical utilization of your fleet.

![]() 26.3 T PAYLOAD WITH PERMANENT PERMIT AROUND GERMANY*

26.3 T PAYLOAD WITH PERMANENT PERMIT AROUND GERMANY*

![]() ECONOMIC FLEET UTILIZATION

ECONOMIC FLEET UTILIZATION

* depending on country-related regulations. Vehicle specification and chosen truck have an impact on the payload which leads to higher or lower permissible payloads

MORE PAYLOAD

- Very light frame construction

- Optimized vehicle extension (optional)

- Higher stability and payload due to center tube design

MORE SAFETY

- Safe loading and transport with a width of more than 2,500 mm with light, stable widening planks

- Lightweight components increase payload and work safety

- Further weight saving with safe TRAFFIDECK™ GO flooring (optional)

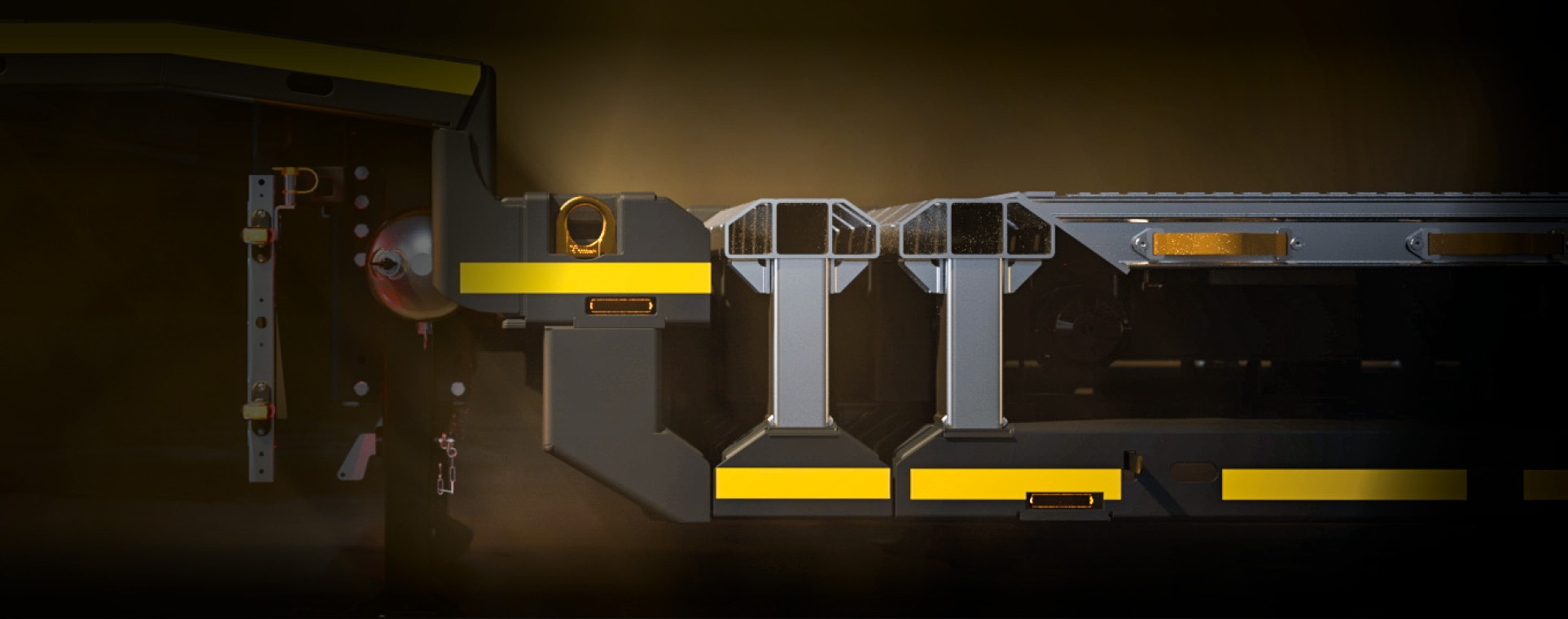

»MEGA« GOOSENECK

With the optional »MEGA« gooseneck of the »STEPSTAR« semi-trailers more loads than ever can be transported with one trailer. The combination of the very low coupling height of a lowliner tractor with the flat construction of the »MEGA« gooseneck results in an extremely low usable loading height. This allows the transportation of wheeled vehicles, divided loads, small parts and even a 40-foot or two 20-foot container within 16.5 m total length. The "MEGA" gooseneck is available for all vehicles of the »STEPSTAR« family.

![]() SIMPLIFIED OBTAINMENT OF PERMITS

SIMPLIFIED OBTAINMENT OF PERMITS

![]() GREATER FLEXIBILITY – ONE VEHICLE FOR MANY TASKS

GREATER FLEXIBILITY – ONE VEHICLE FOR MANY TASKS

PREMIUM COMPONENTS

The use of premium components as a standard gives the »STEPSTAR« semi lowloaders their long service life. The high degree of standardization means that spare parts can be obtained quickly and easily if required.

![]() LIFETIME TEST UNDER THE TOUGHEST CONDITIONS

LIFETIME TEST UNDER THE TOUGHEST CONDITIONS

![]() CONFIRMED GOLDHOFER PREMIUM QUALITY

CONFIRMED GOLDHOFER PREMIUM QUALITY

![]() EFFECTIVE PROCUREMENT OF SPARE PARTS

EFFECTIVE PROCUREMENT OF SPARE PARTS

![]() LOWER TOTAL COST OF OWNERSHIP (TCO)

LOWER TOTAL COST OF OWNERSHIP (TCO)

High quality landing gear for easy leveling on any surface

Low-maintenance BPW axles offering top quality

![]() Simple and fast bearing and brake replacement saves approx. 90 min. per axle

Simple and fast bearing and brake replacement saves approx. 90 min. per axle

![]() Best delivery of spare parts for high vehicle availability

Best delivery of spare parts for high vehicle availability

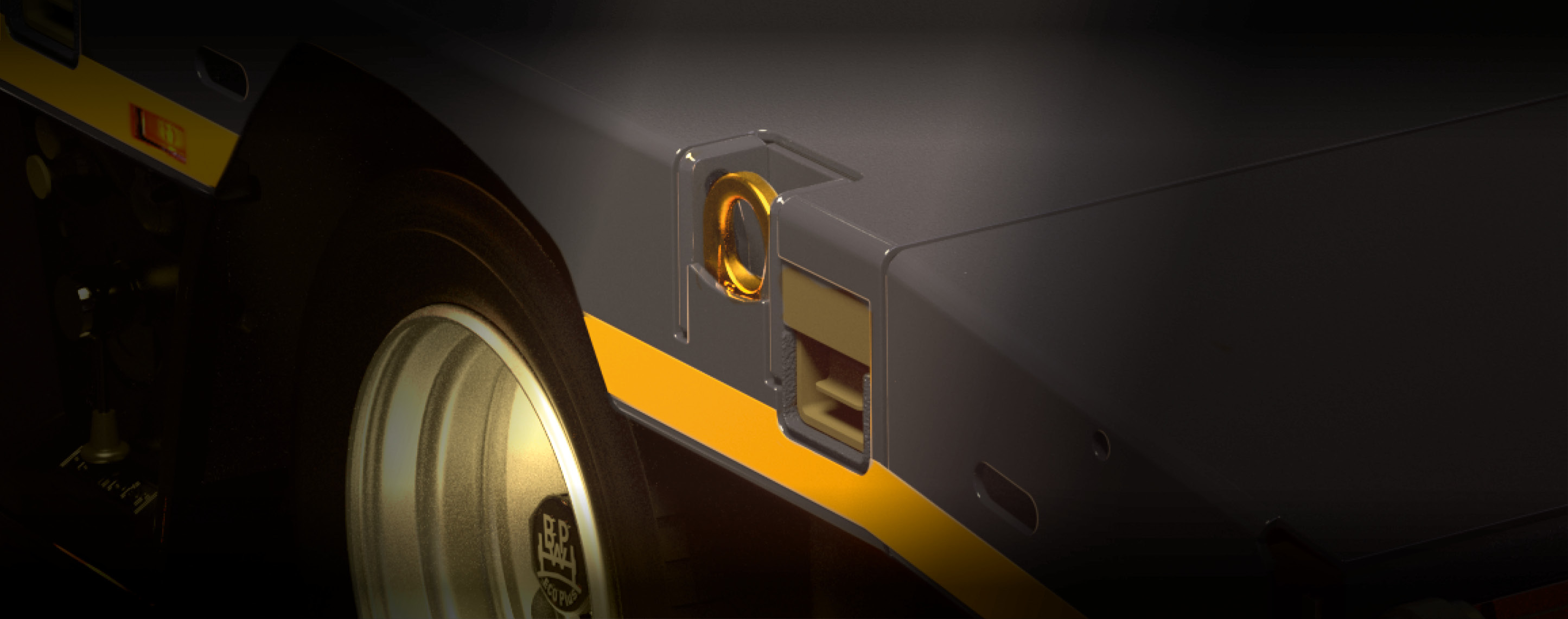

Ultra-modern and robust polymer wings for efficient splash protection and significant weight saving

Tail support legs with convenient foot or optional hydraulic operation

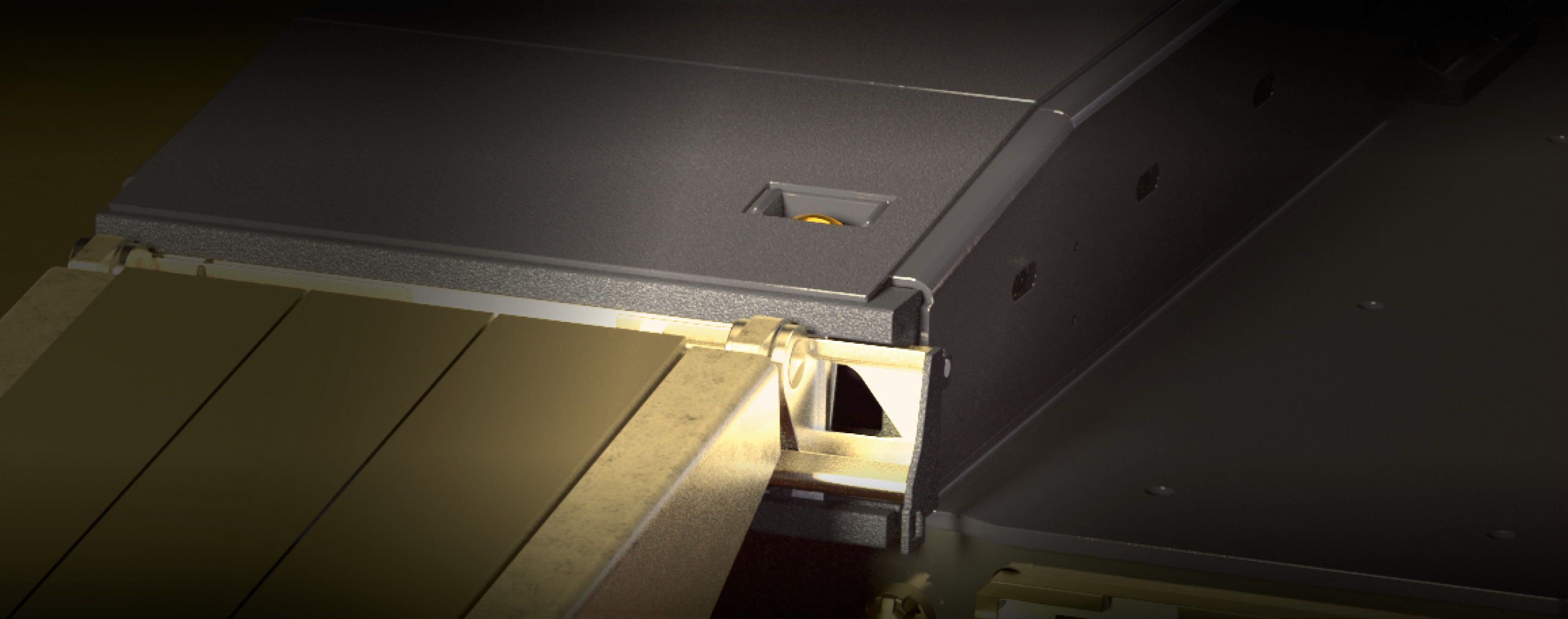

Robust and economical ERMAX full LED lighting system

![]() Impact-resistant lighting

Impact-resistant lighting

![]() Encapsulated connecting plugs for low wear even under extreme conditions

Encapsulated connecting plugs for low wear even under extreme conditions

LOAD SECURING

As an optional special feature, the »STEPSTAR« has positive-locking stake pockets on the gooseneck. The optional TRAFFIDECK™ GO deck covering is also available for enhanced load security and reduced lashing requirements.

![]() FAST AND RELIABLE LOAD SECURING

FAST AND RELIABLE LOAD SECURING

![]() HIGH LEVEL OF SECURITY FOR DAY-TO-DAY OPERATIONS

HIGH LEVEL OF SECURITY FOR DAY-TO-DAY OPERATIONS

![]() IN COMPLIANCE WITH THE STRICTEST REGULATIONS

IN COMPLIANCE WITH THE STRICTEST REGULATIONS

Wader container pockets

![]() Recessed in the loading platform for ease of driving over

Recessed in the loading platform for ease of driving over

![]() Safe transport of containers

Safe transport of containers

Stake pockets

![]() Simple securing of small parts or long material

Simple securing of small parts or long material

![]() Fast, efficient load securing through positive-locking

Fast, efficient load securing through positive-locking

Drive-over recessed lashing lugs on the tail

![]() Retractable in the frame

Retractable in the frame

![]() Optimum lashing angle for efficient lashing to the front

Optimum lashing angle for efficient lashing to the front

Loading platform equipped with RUD Optilash Fix 10 t lashing rings

![]() Retractable

Retractable

![]() Damaged rings can be replaced easily

Damaged rings can be replaced easily

Anchor points in the frame and the excavator recess

![]() Simple securing of small parts

Simple securing of small parts

![]() High load capacity

High load capacity

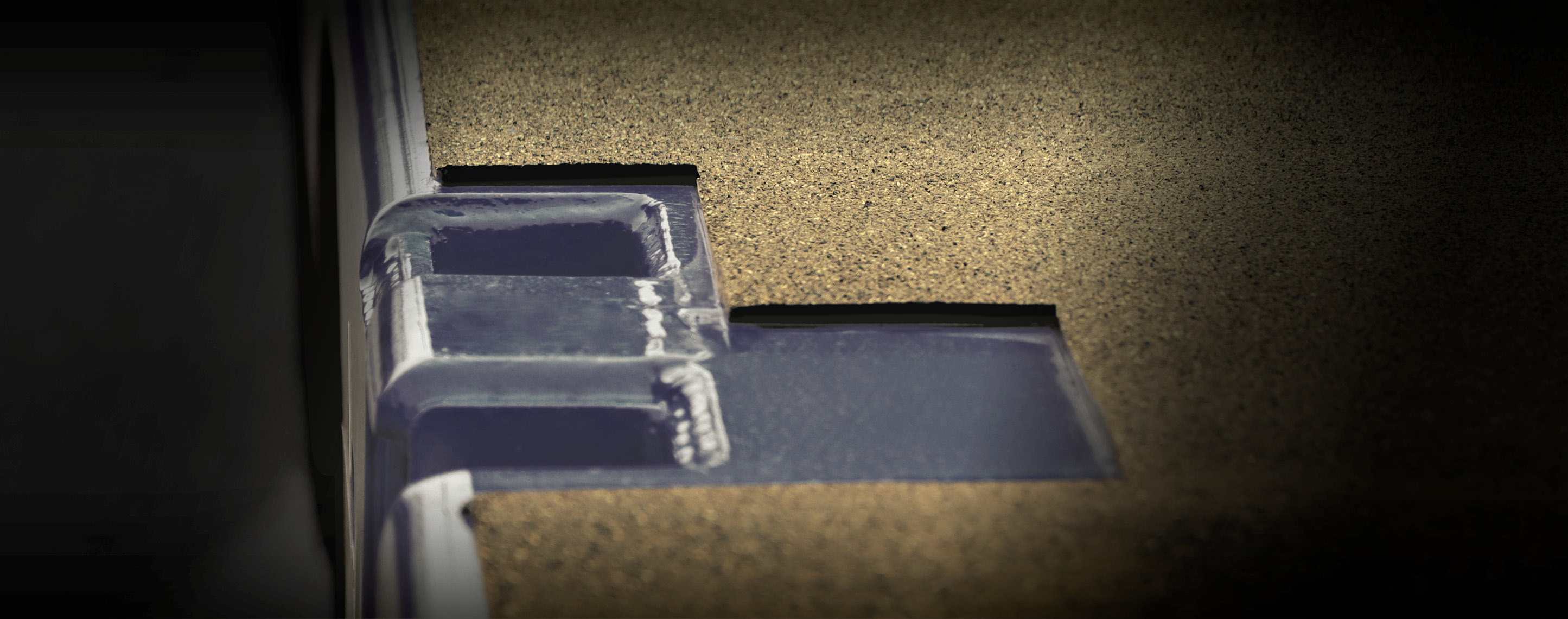

Optional TRAFFIDECK™ GO floor covering

![]() More loading height and 80% lighter compared to conventional rubber mats

More loading height and 80% lighter compared to conventional rubber mats

![]() High friction coefficient ensures optimum load securing

High friction coefficient ensures optimum load securing

![]() Sanding of the loading area ensures safety in all weather conditions

Sanding of the loading area ensures safety in all weather conditions

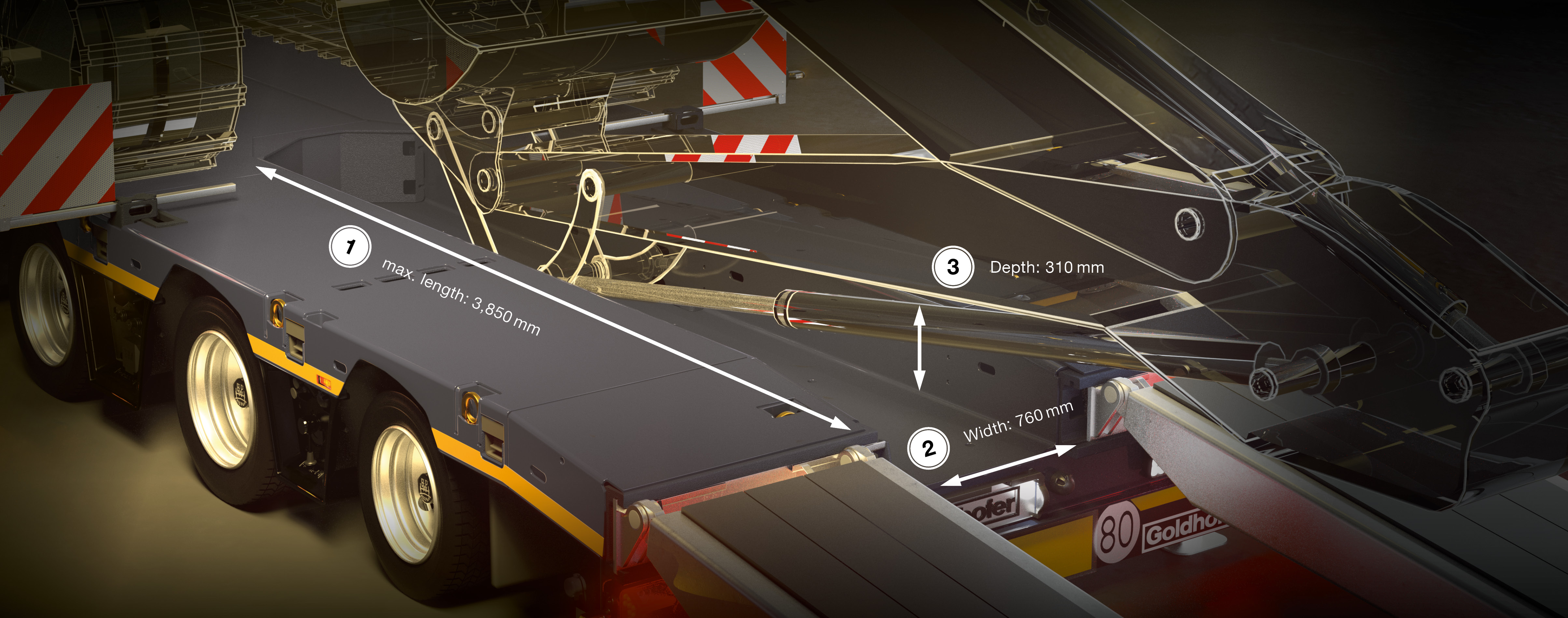

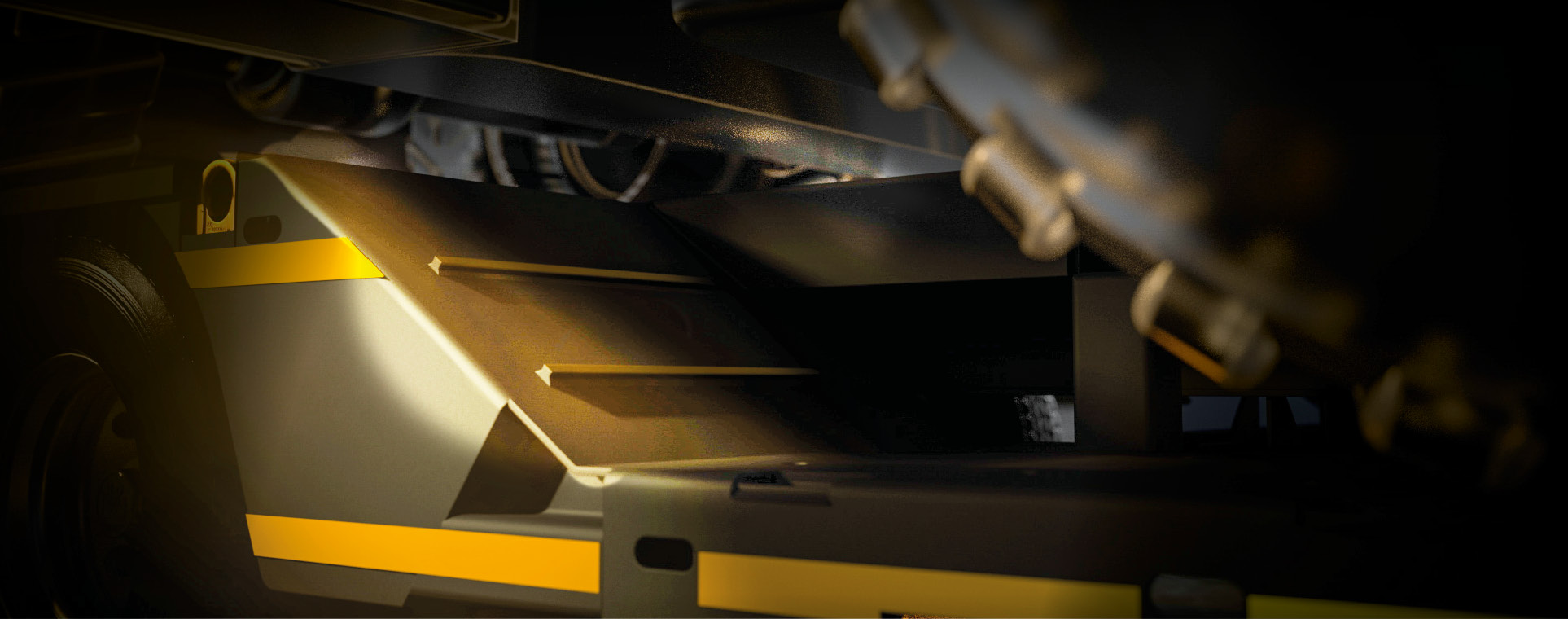

EXCAVATOR BOOM RECESS

The special feature of the extra long and wide excavator recess of the »STEPSTAR« semi lowloaders is that it has no cross members and is open to the rear. This makes it possible to carry even bigger excavator booms while simultaneously reducing overall height. With up to three removable bulkheads, even small parts can be secured efficiently and space-saving.

![]() SIMPLIFIED OBTAINMENT OF PERMITS

SIMPLIFIED OBTAINMENT OF PERMITS

![]() COST-EFFECTIVE TRANSPORTATION

COST-EFFECTIVE TRANSPORTATION

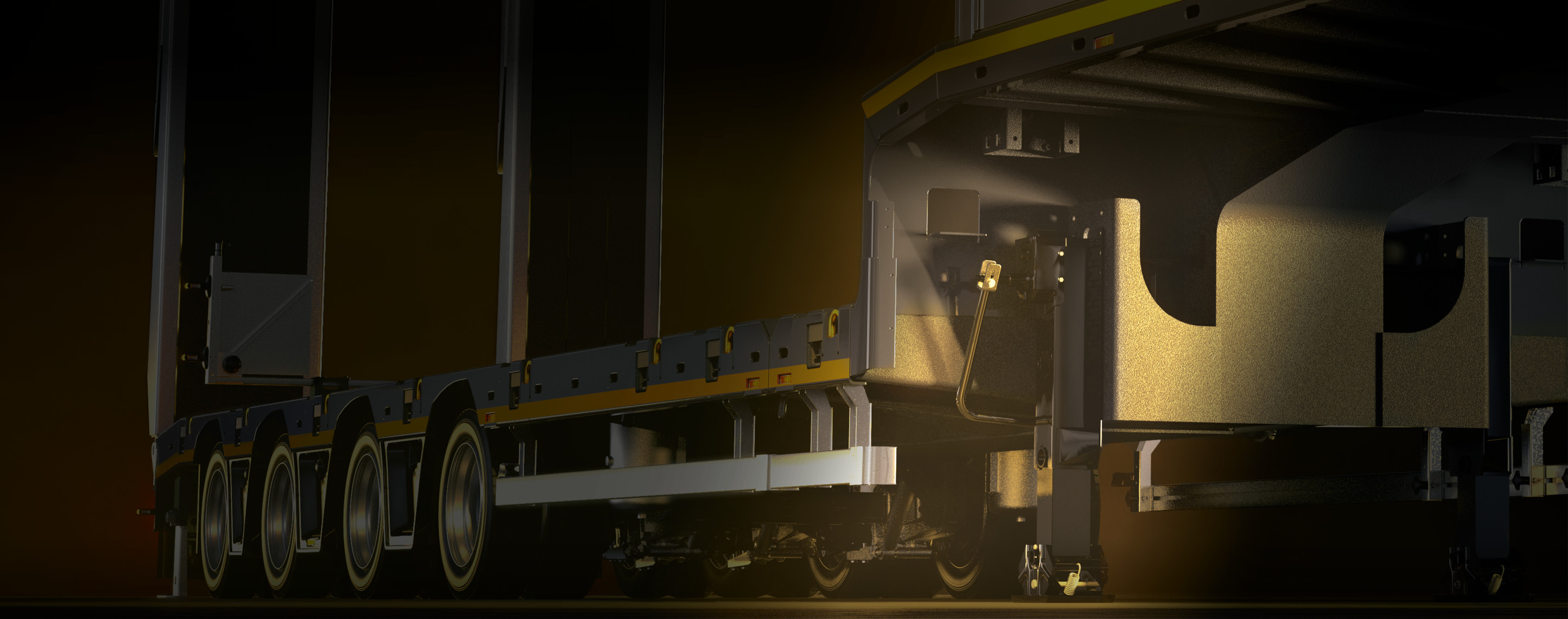

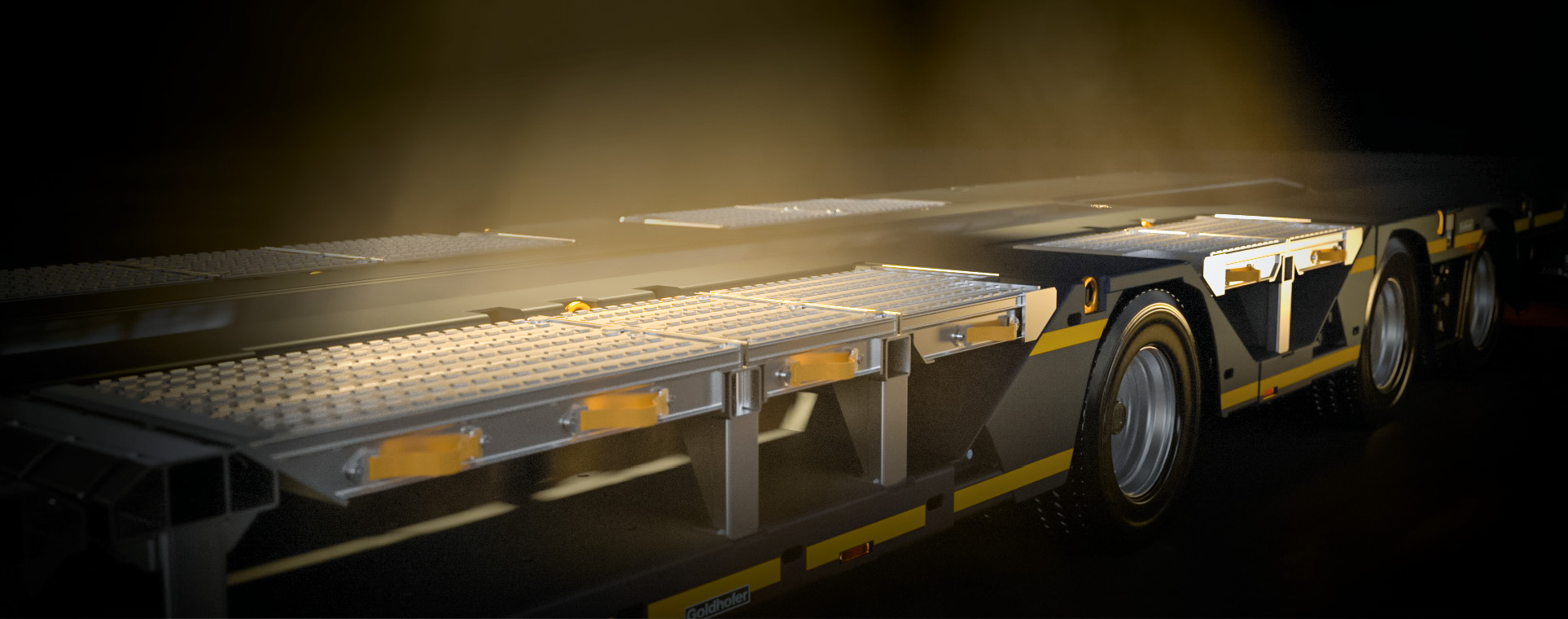

WHEEL RECESSES

»STEPSTAR« semi-trailers are optionally available with one or two wheel recesses. The loading platform can be converted quickly and efficiently for other loads thanks to the well thought-out wheel recess covers. With the extendable vehicle variants in particular, loads with different wheelbases can be transported easily.

![]() FULFILLMENT OF THE MOST STRINGENT HEIGHT GUIDELINES

FULFILLMENT OF THE MOST STRINGENT HEIGHT GUIDELINES

![]() REDUCED SET-UP TIMES FOR DIFFERENT LOADS

REDUCED SET-UP TIMES FOR DIFFERENT LOADS

Extension of the wheel recess by inserting aluminium elements

Low entry angle and climbing rails for safe driving even with low slope angles

High-quality aluminium wheel recess covers, optionally extendable to 3,000 mm

Second wheel recess depth for loads with low ground clearance by using the aluminium covers

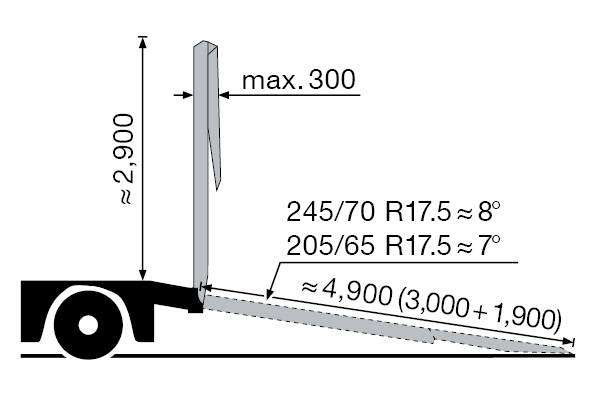

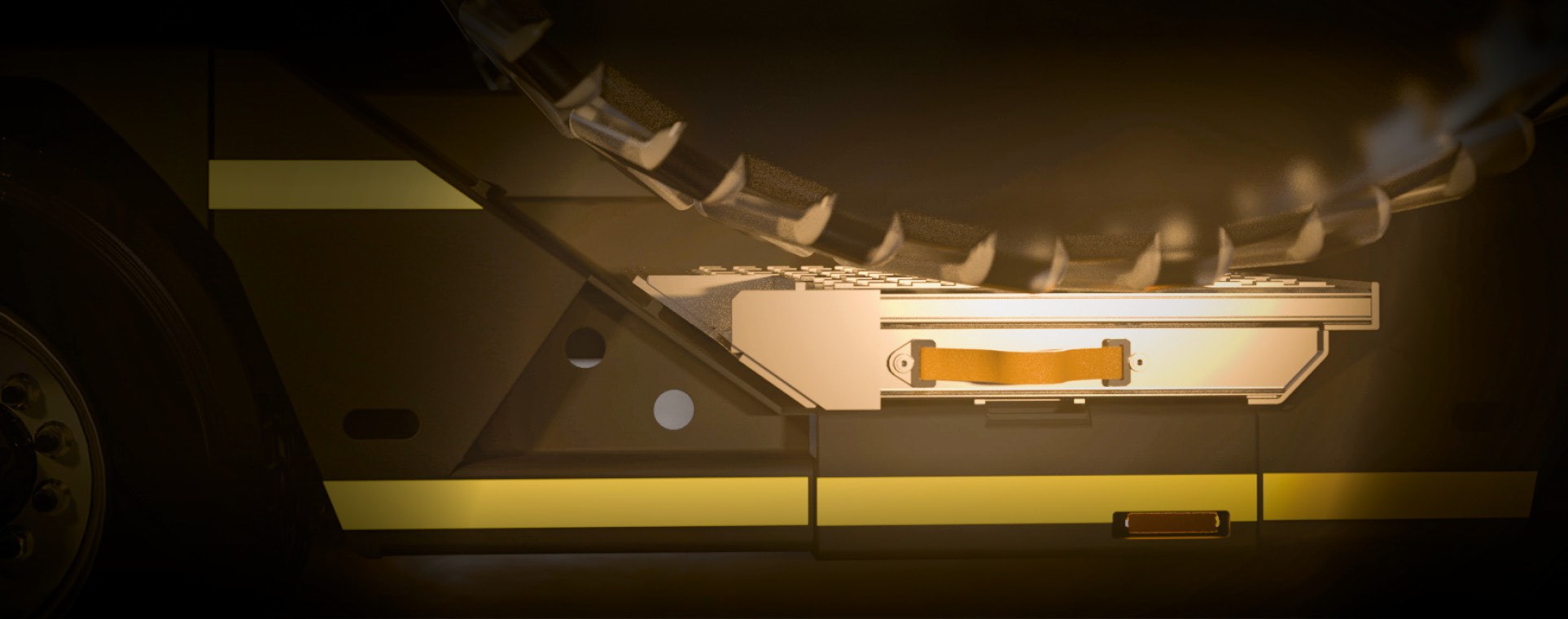

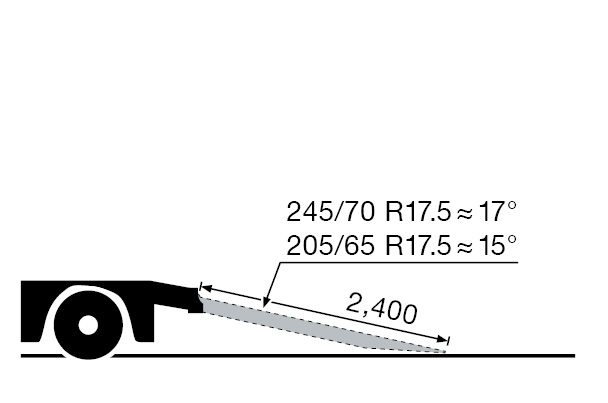

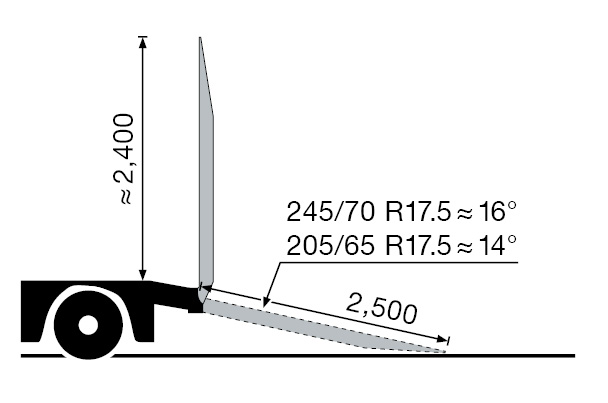

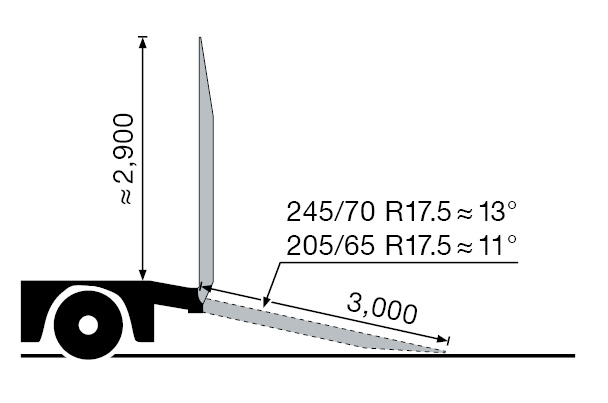

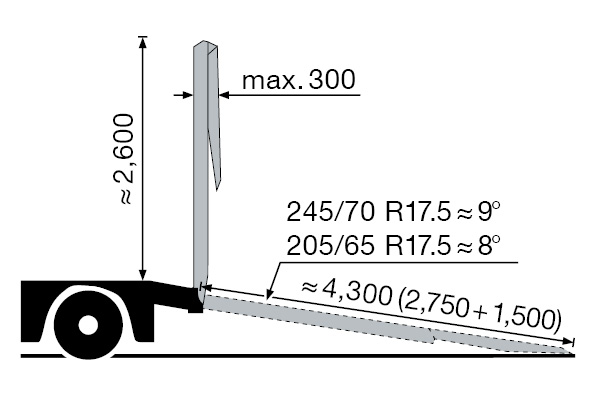

RAMPS

The long and light ramps of the »STEPSTAR« series are a further advantage in day-to-day transport operations. With a low ramp angle and the ground-friendly lowering mechanism, loading is child’s play.

![]() FAST AND EASY LOADING

FAST AND EASY LOADING

![]() EFFICIENT RETURN JOURNEY

EFFICIENT RETURN JOURNEY

Suitable for almost all self-propelled cargos

![]() Up to 3,000 mm width for safe drive-on

Up to 3,000 mm width for safe drive-on

![]() Completely shiftable for 3-wheeled vehicles

Completely shiftable for 3-wheeled vehicles

Safe and convenient operation of the ramps

![]() Optional radio remote control

Optional radio remote control

![]() Integrated ramp protection for time saving and safe transport

Integrated ramp protection for time saving and safe transport

![]() Attachment and removal using a forklift for increased efficiency

Attachment and removal using a forklift for increased efficiency

Retrofitting for all ramps

![]() Staged investment

Staged investment

![]() Flexible approach to the transport situation

Flexible approach to the transport situation

Ramp portfolio

Removable ramps

![]() Capacity 24 t / Width 450 mm

Capacity 24 t / Width 450 mm

![]() Capacity 32 t / Width 600 mm

Capacity 32 t / Width 600 mm

Mechanical folding ramps (one-piece)

Capacity 24 t / Width 600 mm

Capacity 32 t / Width 600 mm

Hydraulic folding ramps (one-piece)

![]() Capacity 38 t / Width 800 mm

Capacity 38 t / Width 800 mm

![]() Capacity 52 t / Width 800 mm

Capacity 52 t / Width 800 mm

Hydraulic folding ramps (two-piece)

![]() Capacity 38 t / Width 800 mm

Capacity 38 t / Width 800 mm

![]() Capacity 52 t / Width 800 mm

Capacity 52 t / Width 800 mm

Hydraulic folding ramps (two-piece)

![]() Capacity 38 t / Width 1,000 mm

Capacity 38 t / Width 1,000 mm